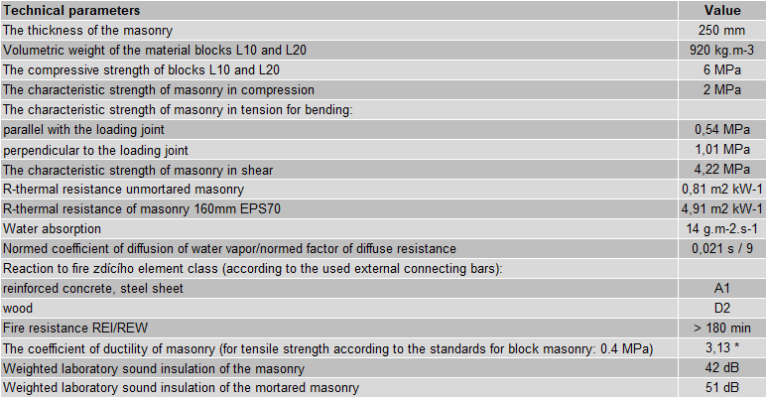

PARAMETERS

STAVSI BLOCKS

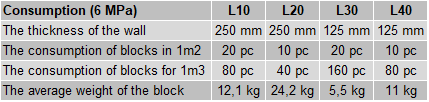

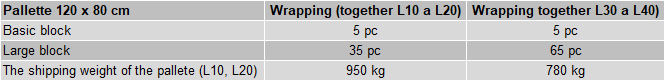

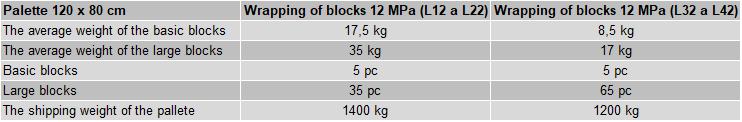

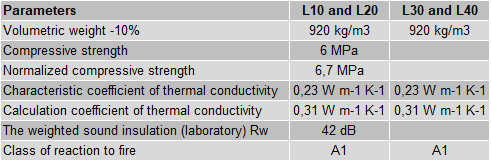

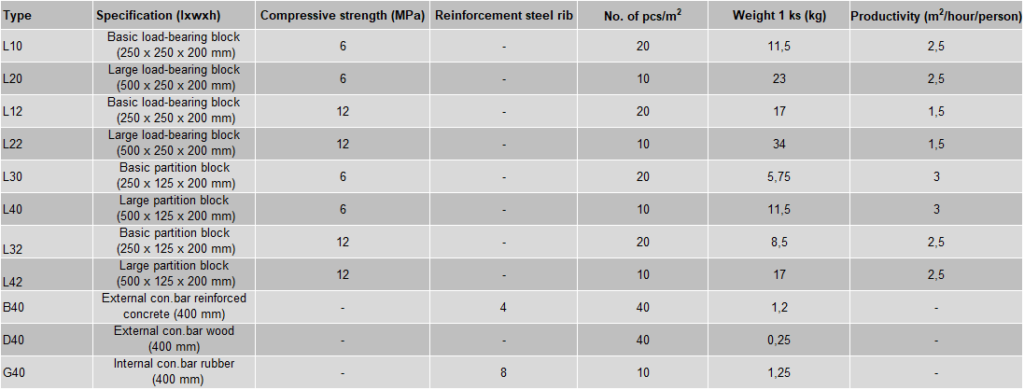

Full blocks are made of lightweight ceramic concrete with Liaporem (concrete mixture lightened with ceramic granules) by the method of pressing while vibrating the mixture in the form of the vibrolisech. Cinder blocks offer a synergy of properties of ceramics and concrete. In particular, the excellent storage and acoustic parameters. The carrier and the circuit blocks are normally manufactured in two strength classes:

- 6 MPa with the designation L10 and L20

- 12 MPa with the label L12 and L22

Blocks in grade 6 MPa are made from a mixture with density of 920 kg/m3 and blocks in the class of 12 MPa are made from a mixture with density 1200 kg/m3.

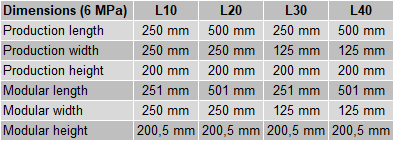

Starting work STAVSI is the basic load-bearing blocks with the designation of the L1x, where x is 0.2 according to the volumetric weight of the material. A derivative work is a large load-bearing blocks with the designation of the L2x. Derived parts are also basic non load-bearing blocks L3x and big non load-bearing blocks L4x. All blocks are sanded – calibrated to a precise height.

STAVSI connecting bars

The foundation of any construction of STAVSI is a construction set. Each building set consists of calibrated with a cinder block and connecting rails, which maximum will consolidate with the neighboring sets in the wall. The connecting strips form an auxiliary connecting material.

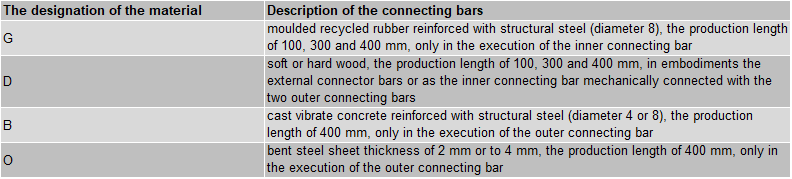

The inner connecting strips are used for inserting and fastening the blocks in the center grooves with a cross section in the shape of a double dovetail (two isosceles trapezoids associated shorter parallel side). The outer tie rails are used for inserting and fastening the blocks in the external grooves on the wall surface with a cross section in the shape of a dovetail (an isosceles trapezoid). Inserting connecting strips into the corresponding groove is formed self-locking joint. Internal and external tie bar is produced in the basic lengths of 400 mm. Rubber and wooden connecting bar is also produced in lengths of 100 and 300 mm. For establishing the walls and in the places of their termination must alternately use the connecting rails with length of 100 mm and 300 mm. In exceptional cases, the use of connecting strips of length 200 mm. If you need to, so the shorter moldings produced from strips with a length of 400 mm as required directly on the construction site with the use of hand saws.

The connecting bar is used for vertical interconnection, both vertically and horizontally successive blocks within the constructed walls. The connecting rails provide a solid connection blocks and predispose the squareness and flatness of the constructed walls. The inner connecting strips can exist as separate products (their cross-section forms a double-dovetail) or it can be created using the two against each other consistently recorded external connecting rails (each with a cross section of dovetail – an isosceles trapezoid) of the same material.

For each block there are a number of material combinations of inner and outer connecting strips. The choice of a particular combination of materials of the connecting strips based on the specific requirements on the construction and that, in the context of what the building or its part is the specific set used.

Recommendations for the combination of materials of the connecting bars:

- For rough construction (RD, apartment buildings, warehouses, workshops, garages) with the usual requirements on the dynamic performance of structures can be used in the internal grooves of the perimeter walls of the reinforced concrete coupling strips and into the walls in the interior of either reinforced concrete or wooden tie bar. Reinforced concrete and wooden moldings are manufactured as one piece, but at the construction site consist of two to each other freely put pieces.

- For rough construction (RD, residential houses, garages, warehouses, workshops) with higher requirements on the dynamic performance of structures can be used in the internal grooves of the exterior and load-bearing walls of reinforced rubber inner tie bar and to the partition walls of reinforced concrete or wooden tie bar. The rubber inner tie bar is manufactured as one piece.

- In general, for all buildings it is advisable to use in places a larger strain (around building openings, around corners, etc.) reinforced rubber inner connecting bar.

- The outer tie strips shall be applied so as to promote the rapid construction. For example, to the interior, where will be used of the plate of the SDK, OSB, building materials, etc., it is advisable to use a wooden tie rails, because at the same time, serves as a grate for the screwing of the plates. In the exterior where there will be insulation, or will be used a thin plaster (perlinka on the glue), apply a reinforced concrete outer tie bar. In places, where anything is glued to the glue, it is recommended to use reinforced concrete outer connecting bar.

- For structures such as fences, etc., shall apply to reinforced concrete and, where appropriate, the rubber reinforced connecting strips, i.e., strips of the materials with minimum degradation.

Packing of connecting bars

The connecting strips are supplied packed on a pallet. In the package are always connecting strips, only one material.

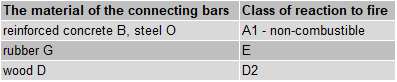

Reaction to fire of the connecting rails according to the material

This means that the class of reaction to fire performance of the wall from the STAVSI can be either A1 or D2. Depending on what material they are made of the outer connecting strips, used on the reference side of the wall. (According to the relevant EU standards, in detail on the www.pavus.cz).

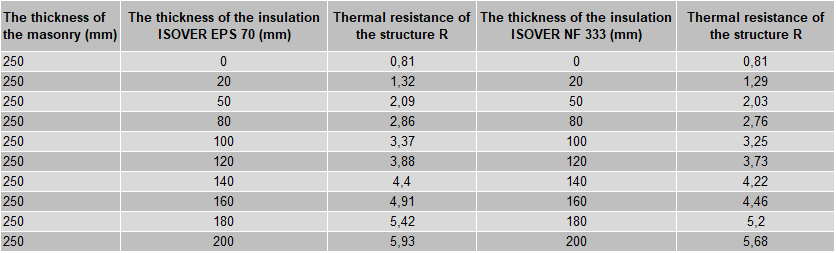

The thermal resistance of laminated veneer walls

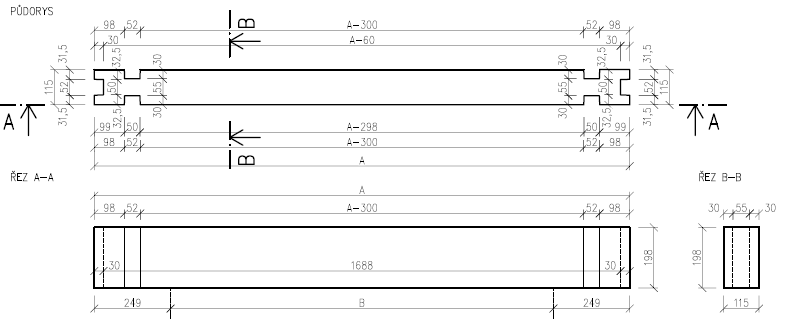

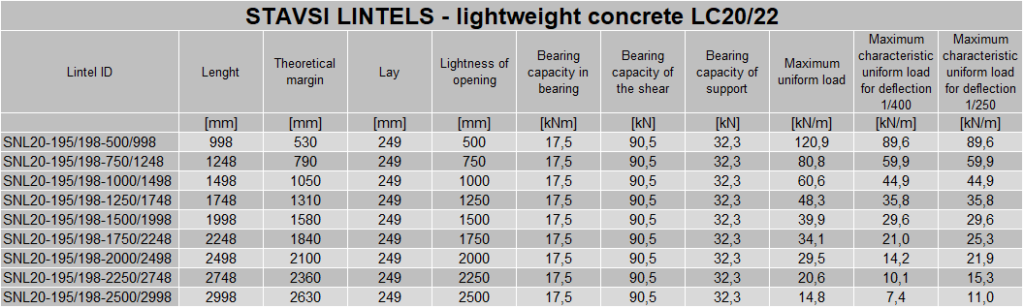

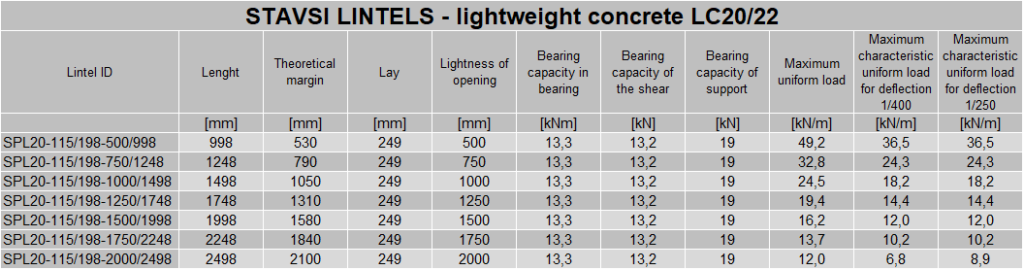

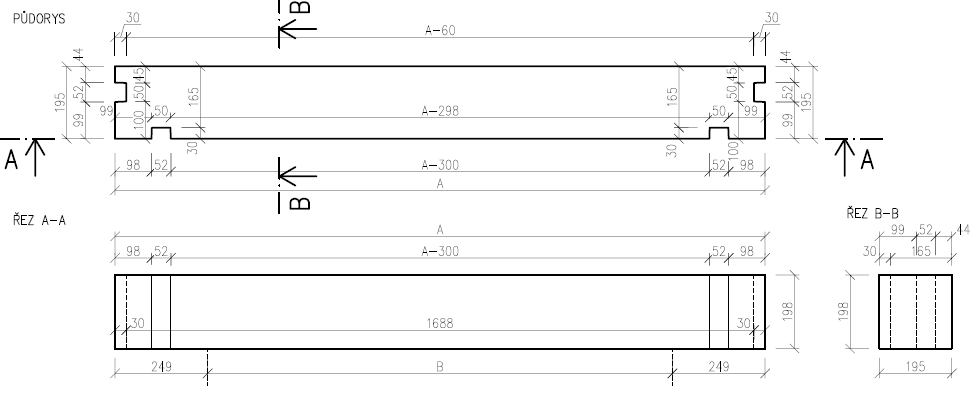

Lintels

Note: loads mentioned without self weight of the lintel (that means load with which can be the lintel itself weighted)

Concrete LC20/22 – D1,6

Reinforcement Bottom 4Ø12 B500A; Top 2Ø8 B500A; Continuous diagonals 2Ø6/100 B500A

Note: loads mentioned without self weight of the lintel (that means load with which can be the lintel itself weighted)

Concrete LC20/22 – D1,6

Reinforcement Bottom 2Ø12 B500A; Top 1Ø8 B500A; Continuous diagonals 2Ø6/200 B500A

Lintel for load-bearing wall

Lintel for partition